In September 2015, the General Assembly adopted the 2030 Agenda for Sustainable Development that includes 17 Sustainable Development Goals (SDGs). Building on the principle of “leaving no one behind”, the new Agenda emphasizes a holistic approach to achieving sustainable development for all.

Simoshi’s Institutional Improved Cook Stoves for Schools and Institutions in Uganda’s Project Activity achieves 9 out of the 17 SDG goals, and below is a table with an explanation on how the project has an impact on the most relevant SDG targets for each of those goals.

SDG 1 – No poverty | Measurement Method: school bursars are usually responsible for all firewood purchases during the school term. Simoshi monitors these firewood expenditures right at the beginning during the baseline survey it conducts in each school, and after the IICS have been deployed. Simoshi collects the amount of firewood spent at the end of each school term and monitors that savings are still achieved compared to the baseline expenditure through the “School Term Update” form.

SDG 3 – Good health and well-being | Measurement Method: The perception of members of the school/institution (staff responsible for cooking) concerning air quality after the introduction of IICS evaluated quarterly on the basis of the results of the “Kitchen Information Update” survey. The question is “How do you perceive air quality when using an IICS?”. The enumerators are instructed to elaborate this question further by asking detailed questions (perceived smoke level, incidents of coughing, respiratory illness, eye infections, etc.).

SDG 4 – Quality education | Measurement Method: Simoshi’s service-oriented approach provides better perceptions and outcomes from users, promoting a positive behavioral change in the kitchen. On-going training and free IICS annual maintenance are the added on values necessary for the behavioral transition to happen. Simoshi empowers the kitchen staff (usually neglected by school managers, badly remunerated and working in unhealthy and poor environments) through the continuous training and monitoring model, following the “Kitchen Management Techniques” and “Firewood Best Practice Manual”, and the “Kitchen Training Assessment” to improve the overall conditions and safety of the kitchen environment.

SDG 5 – Gender equality | Measurement Method: Cooks are usually women who play an instrumental role in raising awareness between their peers and community members about the dangers of utilizing traditional cooking methods. Addressing gender issues in clean energy recognizes that women are key players in health, environmental, economic and climate change issues. Clean cooking results in tangible impacts for women and girls. They play a crucial leadership role in the adoption and use of clean cooking solutions.

SDG 7 – Affordable and clean energy | Measurement Method: Number of schools and institutions with IICS in year y. Sales database and usage survey to confirm the amount of IICS in use and number of participating schools/institutions.

SDG 8 – Decent work and economic growth | Measurement Method: Employment records including evidence for income generation collected by Simoshi for workers involved in the IICS chain. These include stove manufacturers, vendors, data clerks and project officers, extension workers, where applicable. Documents may include employment contracts, payment slips, employment lists and others. Labour standards on sexual harassment and compliance with health and safety guidelines.

SDG 13 – Climate action | Measurement Method: the emission reduction parameter is calculated as a result of IICS meeting the minimum thermal efficiency requirement of 20%. This efficiency is translated into fuel savings compared to traditional stoves used in Uganda. This reduction in fuel consumption is estimated and corresponding CO2 emission reductions are calculated from these savings. The emission reductions are calculated as per the registered PDD and as per the methodology requirement.

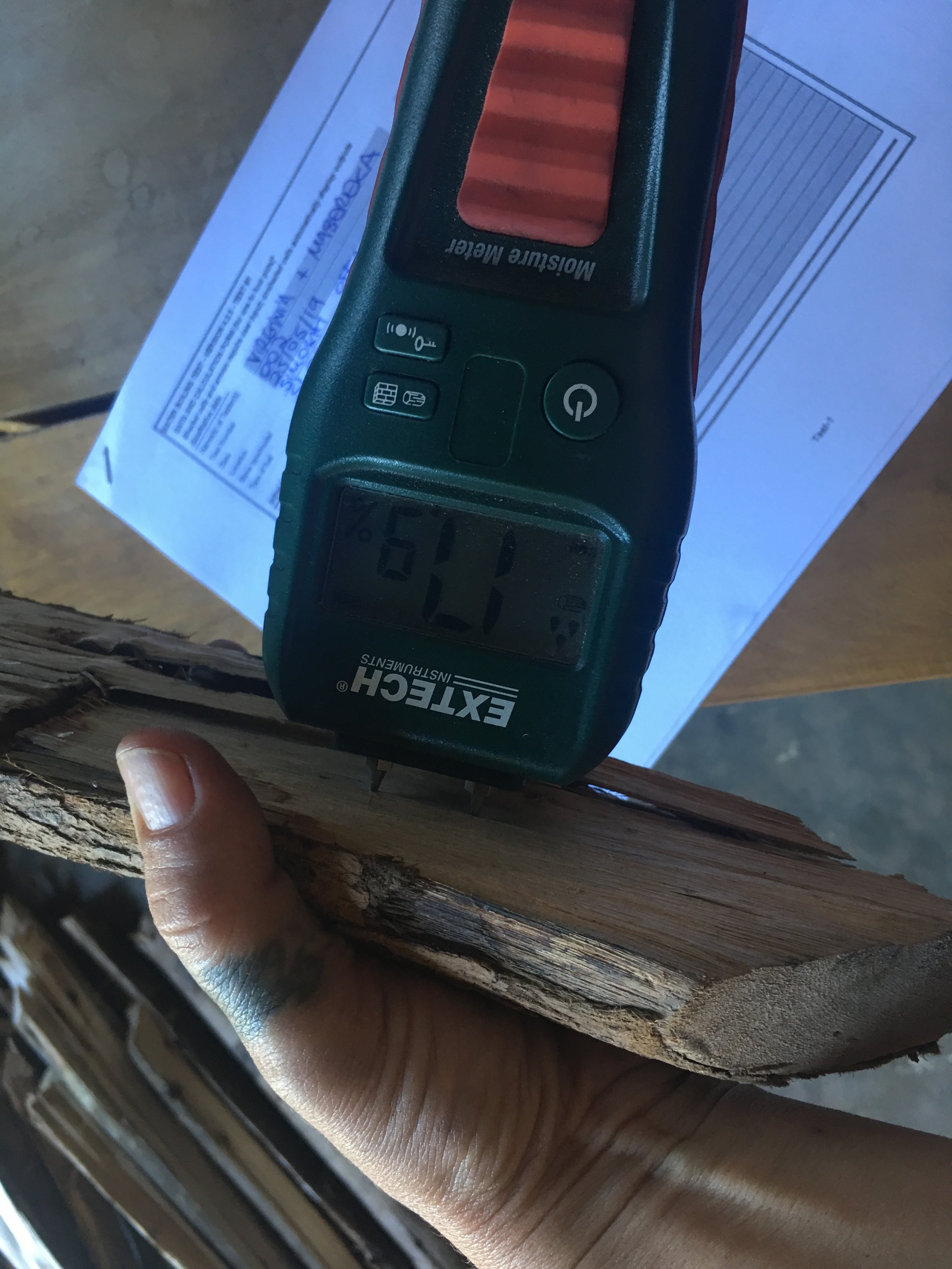

SDG 15 – Life on land | Measurement Method: Simoshi ensures that IICS models from the selected IICS manufacturers are of similar design, following Simoshi’s Quality Assurance and Quality Control Manual (which includes consistency in manufacturing practices and materials used) and Simoshi’s Maintenance Manual that demonstrates comparable maintenance and repair practices on all IICS included under the project activity to ensure the maximum firewood savings are achieved.

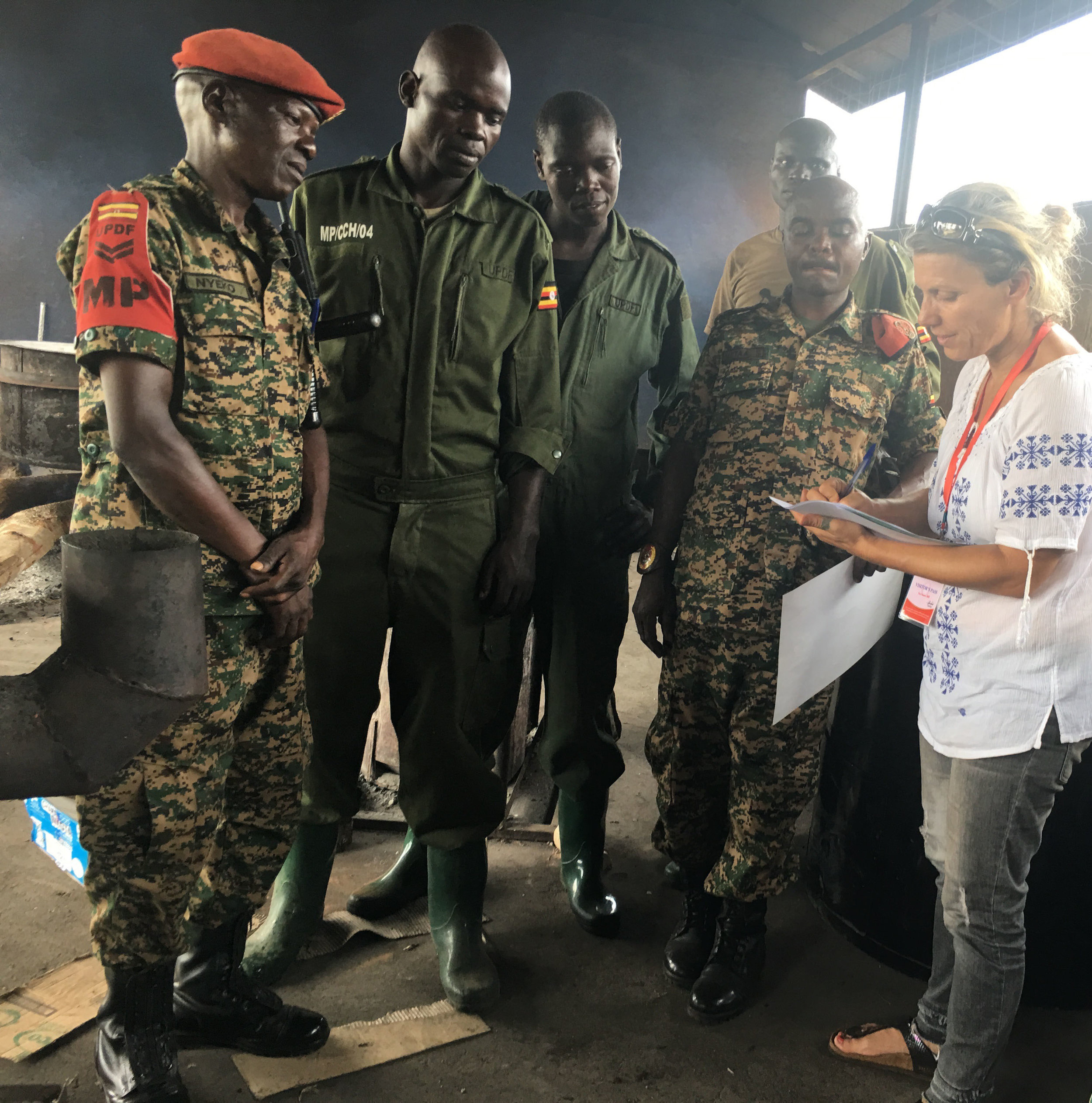

SDG 17 – Partnerships for the goals | Measurement Method: number of Kampala Capital City Authority schools included under the Project Activity, as part of the mutual efforts to move government schools away from traditional cooking practices.